Maine MEP and the Advanced Manufacturing Center at the University of Maine are collaborating on the Center for Additive Manufacturing of Metals to make innovative technologies accessible to manufacturers in Maine and New England.

The custom highly innovative equipment installed at CAMM is bringing Industry 4.0 to Maine. Some of the new equiptment available to manufacturers is described below.

5×10′ 6kw fiber laser cutting system with rotary axis and 4kw laser Directed Energy Deposition (DED), used for cutting sheet metal materials and components used in automation machine builds, as well as tooling and fixturing.

A CNC coordinate measurement machine with surface profiling, which fills a critical need: the ability to accurately measure complex parts, especially for hybrid (additive and subtractive) machining components.

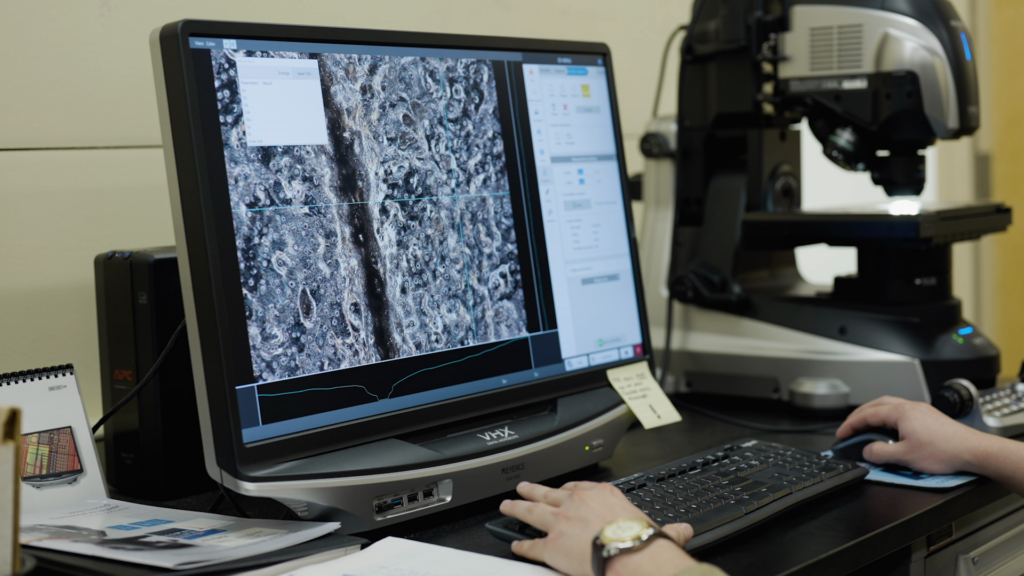

A metrology stacking microscope, which can look at and measure multiple levels of microscopic surface structure to ensure the quality of the additive manufactured

components.

A FARO arm manual CMM with laser line probe for no contact measurements along with 3D scanning and contact probe for contact measurements.

A Desktop Metal Studio System which involves printing parts from a CAD model using a down metal deposition

system and the furnace, which debunks and sinters the part, taking the metal particles and bringing them together to full density.

Read more about how the AMC and Maine MEP assisted Ntension with the development of molds for a new product line.