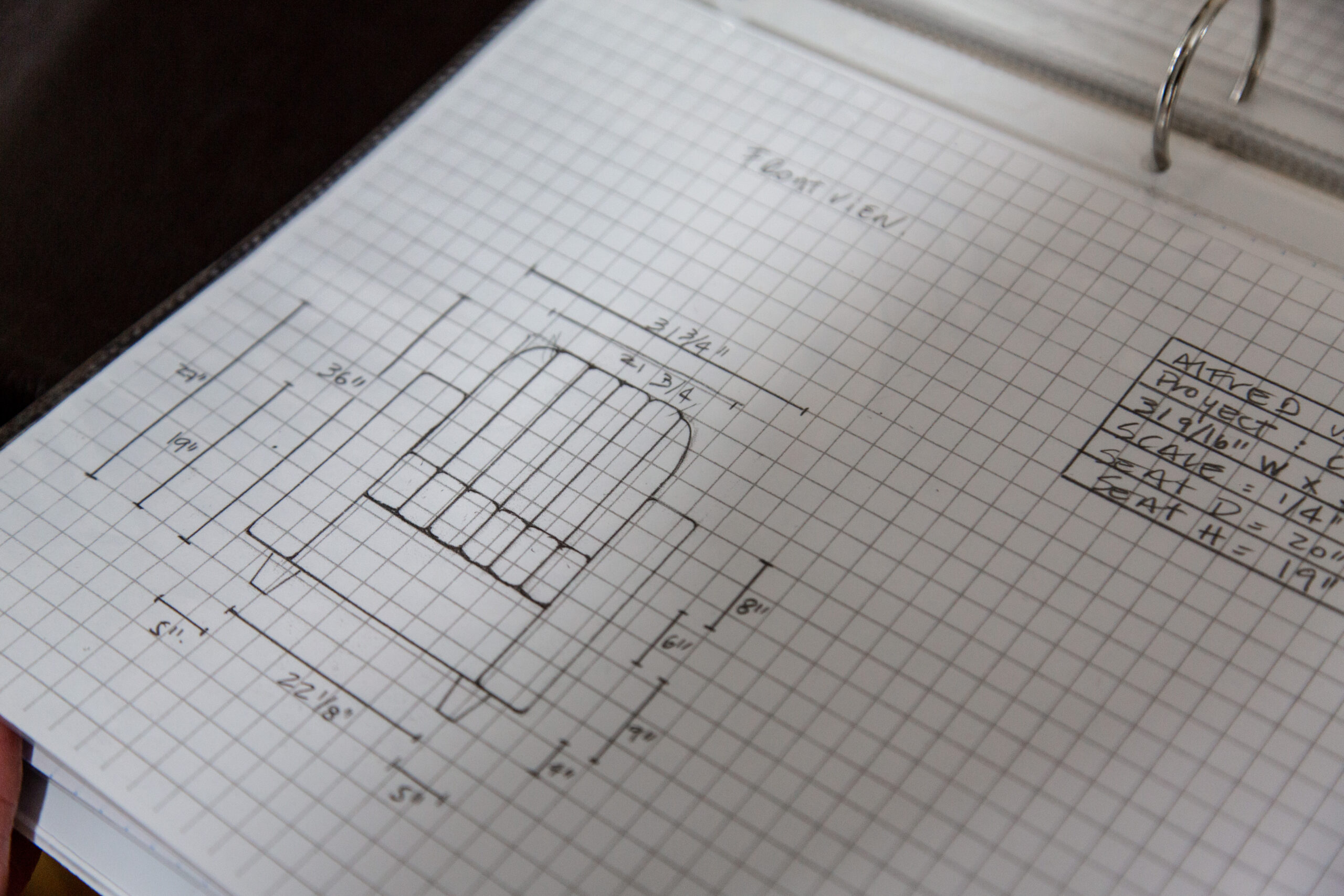

Physical templates and patterns are vulnerable to damage and loss and need to be remade with any changes and updates. Alfred’s Upholstery & CO. now has a Vision Module (AVM) that can turn 2D paper, cardboard, clear plastic, and wood templates up to 105”x83” into DXF files (the standard format for most CAD programs). This is done with extreme accuracy and the ability to eliminate any flaws in physical templates; some templates can be completed in as little as 5-10 minutes.

Having templates stored digitally gives the ability to easily correct or fine-tune them, and quickly reproduce any template that is damaged, lost, or adjusted. Digitizing templates save time and money, improves the accuracy of final products, minimizes errors, and protects against the catastrophic loss of propriety patterns. Alfred’s is offering digitizing service for 2D patterns that is fast and cost-effective; pricing is dependent on the complexity of each pattern. Please call Troy Delano to discuss your project.

Alfred’s Upholstery & CO – 18 Waterboro Rd, Alfred ME – 207-536-5556

How does it work?

“Hi, my name is Silas Delano and I am the lead technician for the Autometrix CNC machine. My job consists of putting patterns into the machine using the overhead digitizing system. This can be done in as quickly as thirty seconds or take up to five minutes. The length of time depends on how complex the pattern is. Another job that I have is cutting the materials on the table. This is a process that consists of laying material out on the table and making sure that all the patterns fit inside the constraints of the material, using a nesting software. After this, I will send a code to the machine and it will start cutting. Depending on the size of the pattern, the cutting process can be completed as quickly as ten seconds, or if it is a large-scale pattern that takes up the whole table space, it can be done in about five minutes. Once cut, I will quality check the pieces, and take them off the table, getting them ready for the next person.”